Winning Fleet

View our fleet

Our fleets

WINNING CONFIDENCE 韦立信心

WINNING DILIGENCE 韦立勤奋

WINNING ENDURANCE 韦立恒久

WINNING FAITH 韦立信念

WINNING GRACE 韦立恩惠

WINNING KINDNESS 韦立慈爱

WINNING LOYALTY 韦立忠诚

WINNING BROTHER 韦立兄弟(新)

WINNING PRIDE 韦立豪迈

WINNING PEACE 韦立和平

WINNING QUEEN 韦立奎恩

SUNNY Boke 阳光博凯

SUNNY STAR 阳光之星

SUNNY SKY 阳光天宇

WINNING MISSION 使命

WINNING HOPE 韦立希望

WINNING NATURE 韦立自然

WINNING PROGRESS 韦立前进

WINNING OCEAN 韦立大洋

WINNING SEA 韦立大海

WINNING RICH 韦立瑞驰

WINNING RISING 韦立锐昕

WINNING SPIRIT 韦立精神

SUNNY LINK 阳光联盟

WINNING ZEPHYR 韦立西风

SUNNY BOFFA 阳光博发

WINNING UNIVERSE 韦立环宇

WINNING TEAM 韦立团队

WINNING VISION 韦立愿景

WINNING WORLD 韦立世界

WINNING EXCELLENCE 韦立卓越

WINNING YOUTH 韦立青年

SUNNY MOREBAYA 阳光马瑞巴亚

SUNNY ROUTE 阳光航线

WINNING RESILIENCE 韦立坚毅

WINNING ANGEL 韦立安吉

SUNNY SAILOR 阳光水手

SUNNY LABE 阳光拉贝

SUNNY KANKAN 阳光康康

SUNNY KINDIA 阳光金迪亚

SUNNY MAMOU 阳光马木

WINNING WEALTH 韦立财富

SUNNY FARANAH 阳光法拉纳

WINNING BRIGHT 韦立百瑞

SUNNY BEYLA 阳光贝拉

SUNNY NZKORE 阳光恩泽

WINNING WISDOM 韦立智慧

WINNING JOY 韦立欢欣

SUNNY COYAH 阳光科亚

SUNNY FRIA 阳光福瑞

SUNNY DABOLA 阳光大宝

Ship owning

As a global leader in the transportation of bauxite and breakbulk cargoes, Winning International Group continues to expand its fleet by seizing market opportunities and strengthening its operational capacity. The Group currently operates and controls nearly 150 vessels, serving major shipping routes and ports around the world.

Winning’s owned fleet comprises nearly 60 Capesize bulk carriers, with a combined deadweight nearly 12 million tonnes. This places the Group among the world’s top operators in terms of shipping capacity, with an annual cargo throughput of nearly 100 million tonnes. The Group’s core cargoes include bauxite, iron ore and breakbulk shipments, supported by key trades such as West Africa bauxite transport, Brazilian and Australian iron ore routes, and breakbulk services from China to West Africa.

Shipping remains the cornerstone of Winning International Group. We continue to expand and modernise our fleet with the aim of building a green, safe, efficient and highly competitive maritime force that upholds strong corporate responsibility. The Group is currently constructing sixteen 325,000-DWT WinningMax-class ore carriers in collaboration with CSSC and Hengli Heavy Industries. These vessels significantly reduce energy consumption per tonne-mile and feature methanol-ready designs, paving the way for future zero-carbon long-haul operations.

Shipping Operation

Shipping operations constitute the core business of Winning International Group.

To support end-to-end maritime operations, the Group has established a comprehensive professional structure comprising the Chartering Department, Operations Department, Commercial Department, Insurance Affairs Department, and Legal Department.

The Chartering Department formulates fleet operating strategies and capacity planning, leads market development, negotiates chartering agreements, arranges voyages, and prepares operating budgets. It serves as the strategic hub for fleet deployment and global maritime operations.

The Operations Department ensures the safe, efficient, and cost-effective performance of the fleet. It designs optimal voyage plans, manages vessel scheduling, executes contracts, and provides customers with stable, reliable, and high-quality transport services.

The Commercial Department oversees financial settlement and cost control for the shipping division. It is responsible for reviewing all shipping-related revenues and expenses, calculating laytime and handling disputes, and ensuring timely freight collection to safeguard the Group’s commercial interests.

The Insurance Affairs Department builds a comprehensive risk-protection framework covering the Group’s entire “shipping–mining–railway–port” value chain. It manages insurance arrangements for the ocean-going fleet and logistics fleet, coordinates engineering and liability insurance for the construction and operation of mining areas, railways, and ports, and oversees expatriate employee insurance, loss-prevention training, and claims handling across all insurance programmes.

The Legal Department manages the Group’s maritime legal affairs, compliance, risk control, and dispute resolution. It conducts contract reviews, oversees regulatory adherence, and handles litigation and arbitration matters, ensuring the Group’s operations remain secure, compliant, and resilient.

Through this integrated and highly specialised organisational system, Winning International Group’s shipping division continues to operate with efficiency, discipline, and sustainable competitiveness in the global maritime market.

Ship Management

Winning International Group operates its own fully independent ship management company — Qingdao Winning International Ship Management Co., Ltd.

The company is supported by a highly efficient, reliable, and disciplined professional team, comprising seasoned ship management experts, corporate management specialists, and experienced maritime technical personnel. Many of its senior captains and engineering superintendents graduated from leading maritime academies and have served for many years on international trading vessels, bringing extensive operational expertise and comprehensive ship management experience.

The Ship Management Department is staffed by nearly 40 senior chief engineers who serve as technical superintendents. They are responsible for the technical management of both the Group’s bulk carrier fleet and logistics fleet, ensuring that all vessels remain in optimal technical condition.

Daily management is powered by an advanced Ship Management Information System (SMIS), enabling digitalised, systematic, and traceable ship management. The company is also committed to building its own cadre of professional seafarers and has been accredited by the China Maritime Safety Administration as a certified crewing agency. Its goal is to develop a resilient, responsible, adaptable, and highly efficient “Winning Iron Fleet” of seafarers.

In its management philosophy, the company upholds maritime safety as its highest priority and strictly adheres to the International Safety Management (ISM) Code and relevant environmental regulations. Its Safety and Environmental Protection Policy is:

“Ensure Safety, Protect the Environment, Safeguard Health, Deliver Quality Service.”

The company guarantees adequate resources and shore-based support for its vessels and, through rigorous management, risk control, and continuous training, consistently enhances the safety awareness, environmental responsibility, and emergency response capability of all employees. This ensures the Winning fleet operates with the highest safety standards while contributing to the protection of a cleaner and healthier ocean.

Transshipment

Winning International Group’s maritime logistics division is supported by a team of experts with decades of transshipment experience, together with a highly trained multinational crew from Indonesia and other countries. The team delivers consistently high standards of offshore operational performance.

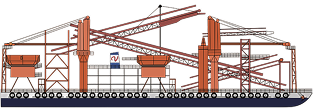

The division currently operates and manages 13 modern large-scale floating cranes, three Floating Transfer Units (FTUs), and nearly 200 barges, offshore tugs, port-assist tugs, bunker vessels and floating docks, forming a comprehensive and large-scale offshore transshipment system with industry-leading capabilities.

The Group’s latest FTU in operation achieves a loading rate of 4,000 tonnes per hour and is engineered to maintain stable and continuous performance even under adverse sea conditions, significantly enhancing the safety and reliability of long-distance transshipment operations.

With its extensive fleet and advanced operational systems, Winning International’s maritime logistics network provides an annual offshore transshipment capacity of 100 million tonnes, delivering efficient, competitive and highly reliable maritime logistics solutions to clients around the world.

Winning Indonesia

Winning International Group entered the Indonesian offshore transshipment market in 2012 and quickly secured a strong foothold, becoming an important industry player by early 2014.

Building on this solid foundation, the Group established its own dedicated crewing entity — Winning Logistics Ship Management Service (WLSMS). What began with manning two Floating Commodity Terminals (FCTs) and two tugboats has now grown into the primary crewing provider for Winning International Group’s fleet operating in Guinea, West Africa.

Today, WLSMS manages more than 1,200 professional seafarers, serving across Floating Cranes (FC), Floating Commodity Terminals (FCT), tugboats and ocean-going vessels. Looking ahead, we plan to expand this workforce to 3,500 seafarers to support the Simandou Project — while continuing to contribute to local employment in Indonesia and supplying highly skilled maritime professionals to the global labour market.

WLSMS is committed to delivering high-quality seafarers in full compliance with international maritime standards. To achieve this, we have developed a comprehensive training framework and rigorous recruitment processes to ensure that only the most qualified talents join our team.

At the same time, the company places strong emphasis on crew welfare. We have introduced the Seafarers’ Family Medical Insurance Scheme and the Children’s Scholarship Programme to enhance the stability and long-term development of our Indonesian seafarer workforce.

SMB-Winning Consortium

A World-Class Bauxite Project

While consolidating its core strengths in shipping, Winning International Group has steadily expanded upstream along the industrial chain. In 2015, together with China’s Shandong Weiqiao Group, Shandong Port Group’s Yantai Port Group, and Guinea’s UMS, Winning jointly established the SMB–Winning Consortium, marking its formal entry into large-scale bauxite development in Guinea, West Africa.

In Guinea, the Consortium established Société Minière de Boké (SMB), Winning Africa Port, and Winning Consortium Railway Guinea, responsible respectively for mining operations, port construction and operation, and railway construction and operation. These entities together form a fully integrated value chain from resource extraction to transportation, significantly reinforcing the Group’s strategic positioning in global resource logistics.

By the end of 2025, the SMB–Winning Consortium had invested a cumulative USD 3.5 billion in infrastructure in Guinea and directly employed more than 10,000 local staff. A further 20,000 people are employed by subcontractors and service providers supporting the project, bringing total job creation to over 30,000 positions nationwide.

According to estimates by the International Monetary Fund, the Consortium’s bauxite project contributes approximately 6% to 7% of Guinea’s national GDP. Driven by sustained growth and operational efficiency, the Consortium’s bauxite shipments are expected to exceed 90 million tonnes in 2026. As a result, Guinea has become China’s largest source of bauxite, supplying around half of China’s annual imports, and has firmly established itself as one of the world’s leading bauxite producers and exporters.

Winning Consortium Simandou

Simandou Iron Ore Project

Building on a decade of deep-rooted presence in Guinea, together with mature project expertise and a strong local foundation, and under the strategic vision and forward-looking leadership of Chairman Sun Xiushun, Winning International Group once again joined hands with Shandong Weiqiao Group to establish Winning Consortium Simandou. The consortium successfully secured the mining rights to Blocks 1 and 2 of the Simandou iron ore deposit. With the strong support and active participation of the Guinean government, Winning Consortium Simandou has partnered with China Baowu, Rio Tinto and Aluminum Corporation of China to jointly advance the world’s largest greenfield mining project—the Simandou Iron Ore Project.

Simandou hosts world-class open-pit, high-grade iron ore resources, with an average grade of 65.5%. Among them, Blocks 1 and 2—holding reserves exceeding 1.8 billion tonnes—are jointly developed by Winning Consortium Simandou and China Baowu, and rank among the most promising and strategically significant iron ore resources globally.

To ensure the efficient evacuation of iron ore, and driven by Chairman Sun Xiushun’s integrated “mine–railway–port” development philosophy, the Simandou infrastructure programme includes the concurrent construction of the 630-kilometre Trans-Guinean Railway, directly linking the mining area to Morebaya Port in southwestern Guinea. The port is equipped with four high-efficiency barge-loading berths, each capable of loading up to 12,000 tonnes per hour. After six years of challenging construction, the railway and port systems were fully completed by the end of 2025 and entered operation, enabling ore shipments and laying a solid foundation for an annual combined transport capacity of 120 million tonnes serving both the WCS mining area and the Simfer mining zone—forming a globally competitive logistics system.

As the largest, most complex and most widely participated multinational integrated project since Guinea’s independence, the Simandou Project represents far more than resource development alone. It is a powerful engine for advancing national industrialisation, promoting balanced regional development and improving community livelihoods. What it carries is not only Guinea’s vision for the future, but also a shared commitment by all partners to build a sustainable and prosperous tomorrow together.

Boké Port

Constructed by Winning Consortium International Engineering Company, Boké Port in Guinea currently comprises two port zones and a central dispatching centre, forming a well-structured and fully integrated port complex.

Port Zone I—Katougouma Port—was completed and commissioned in 2015. Covering an area of 0.96 square kilometres, it is equipped with fixed cranes and a conveyor belt loading system, with an annual shipping capacity of 30 million tonnes. Port Zone II—Dapilon Port—has undergone continuous expansion since its completion in 2016. It now spans approximately 8 square kilometres, features eight berths, and has an annual shipping capacity of around 65 million tonnes, making it one of the largest and most capable bauxite loading ports in Guinea.

Boké Port primarily serves bauxite loading and export operations, as well as the handling of production and construction materials. Leveraging the favourable navigation conditions of the Nunez River and its hinterland advantages, the port has established an efficient and mature inland barge transportation system. It stands as a core hub in Guinea’s bauxite export supply chain, providing strong support for large-scale and continuous shipments.

Morebaya Port

Constructed by Winning Consortium International Engineering Company, the Port of Morebaya is located in Forécariah Province in southern Guinea, on the east bank of the upper estuary of the Morebaya River. The port occupies a land area of approximately 3.44 million square metres.

The port has completed four 12,000-tonne ore barge-loading berths, with a total quay length of 693 metres. Upon full completion, the port’s annual iron ore throughput capacity is expected to reach 120 million tonnes. In addition, it is equipped with two 8,000-tonne general-purpose berths, providing annual handling capacities of 2.5 million tonnes of general cargo and 578,000 tonnes of petroleum products, respectively.

Dapilon-Santou Railway

In March 2019, the SMB-Winning Consortium invested USD 1.2 billion to launch the construction of the Dapilon–Santou Railway — the first modern railway built in Guinea in nearly half a century.

The line begins at the Port of Dapilon in the Boké region, passes through the Consortium’s Block 122 mining zone, as well as the Henan International and Chinalco mining areas, before reaching the Santou mining zone in the Kindia region.

The railway extends 125 kilometres and comprises 21 bridges, two tunnels, 128 culverts, and six stations. As a key supporting facility for mining and transportation in the Santou area, it also serves as essential shared infrastructure for the bauxite operators along the route.

Since entering operation in June 2021, the Dapilon–Santou Railway has maintained stable performance, with an annual transport capacity of approximately 52 million tonnes, providing sustained and robust support to the development of Guinea’s bauxite industry.

TransGuinéen Railway

To support the large-scale development of the Simandou Iron Ore Project, all participating partners jointly completed the construction of the 630-kilometre “TransGuinean Railway” (also known as the MaXi Railway), a strategic national corridor that links the Simandou mining area in the southeast to the Morebaya Port on Guinea’s southwestern coast. The railway forms the backbone of the project’s export logistics system and is one of the most critical components of the overall infrastructure package.

The TransGuinean Railway comprises 12 stations, 206 bridges with a total length of 79.17 kilometres, and 4 tunnels totalling 27.55 kilometres, resulting in a bridge-to-tunnel ratio of 19.4%—a level of engineering complexity rarely seen in the region. The project involved approximately 69.53 million cubic metres of earthworks, traversing mountains, river valleys, and dense rainforest terrains, making it the largest and most technically demanding railway project in Guinea’s history.

Thanks to the close collaboration and sustained commitment of all partners, the railway was fully completed and commissioned by the end of 2025. With an annual transport capacity of 120 million tonnes, the TransGuinean Railway provides robust, reliable, and long-term logistical support for both the WCS and Simfer mining blocks, ensuring the smooth evacuation and export of Simandou’s high-grade iron ore for decades to come.